The Comprehensive Guide to Auto Camshaft Manufacturers

The automotive industry is undoubtedly one of the most vital sectors globally, powering economies and providing countless job opportunities. Within this intricate web, the role of auto camshaft manufacturers stands out, especially in the diesel engine component sector. This article explores the essence of camshaft manufacturing, its significance in diesel engines, and how it impacts the quality of spare parts suppliers. Join us as we delve deep into the world of auto camshaft manufacturing, ensuring that you are well-informed and equipped to make the best choices for your automotive needs.

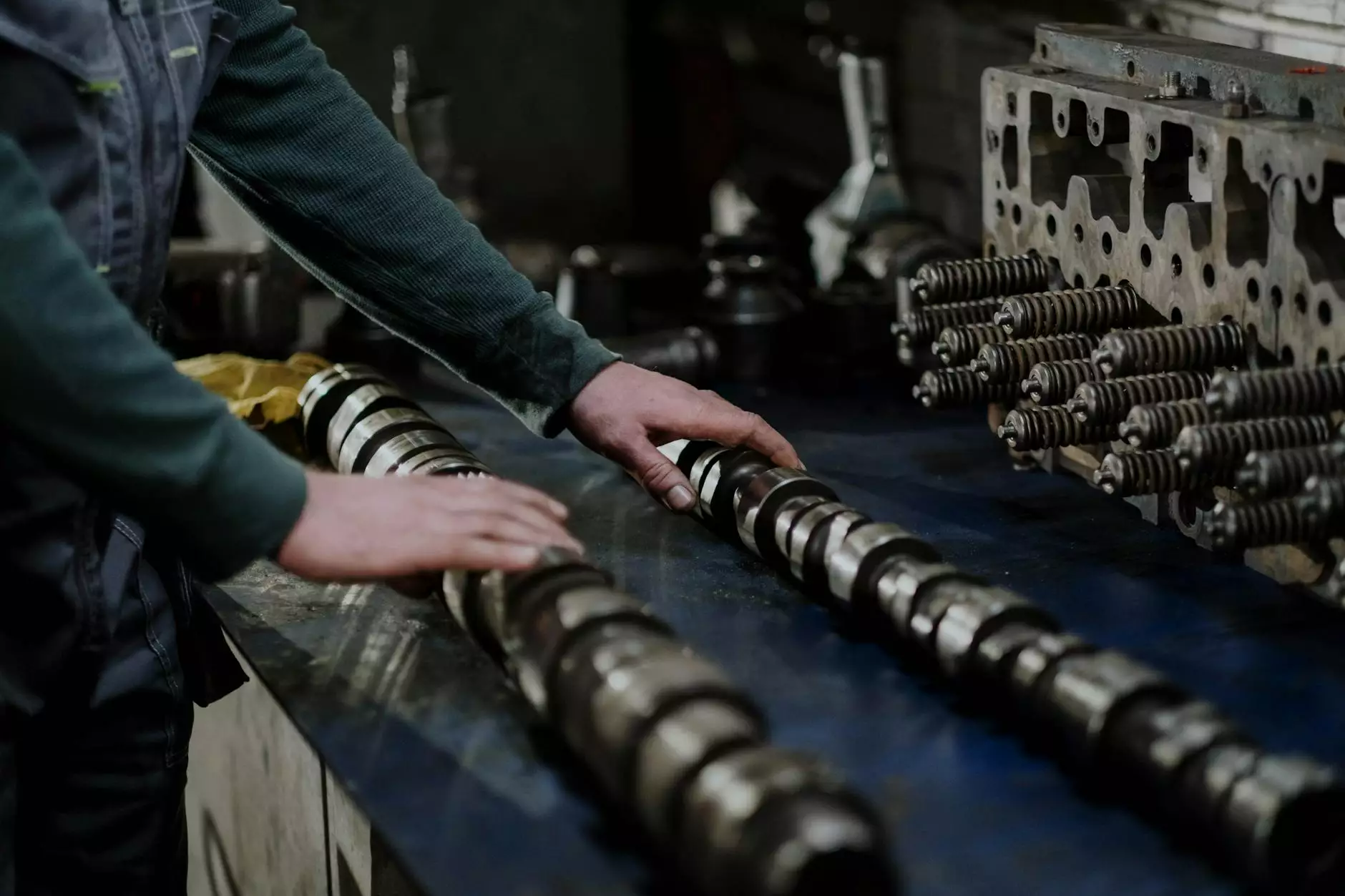

Understanding the Camshaft

To appreciate the work of auto camshaft manufacturers, we first need to understand what a camshaft is and its role in an engine. A camshaft is a crucial component in an internal combustion engine, responsible for controlling the opening and closing of the engine's valves. This part ensures that the engine operates efficiently by regulating the air-fuel mixture intake and exhaust gas exit. The camshaft's design and functionality can significantly affect the engine's performance, making it a vital element in engine design and manufacturing.

The Importance of Quality in Camshaft Manufacturing

When it comes to manufacturing camshafts, the quality of the material and precision in engineering are paramount. High-quality camshafts contribute to improved engine efficiency, reduced emissions, and enhanced overall performance. Here are some reasons why quality matters:

- Enhanced Engine Performance: Quality camshafts provide better timing and valve operation, leading to optimal performance.

- Durability: High-quality materials withstand wear and tear, ensuring a longer lifespan.

- Improved Fuel Efficiency: Precise valve timing can lead to better fuel consumption and lower operational costs.

- Emissions Control: Properly designed camshafts can significantly reduce harmful emissions, meeting regulatory standards.

The Role of Auto Camshaft Manufacturers

Auto camshaft manufacturers play a crucial role in the automotive supply chain, especially within the niche of diesel engine parts. These manufacturers not only produce camshafts but also engage in ongoing research and development to innovate and enhance their products. Here are some of the primary functions of auto camshaft manufacturers:

1. Design and Engineering

One of the primary responsibilities of auto camshaft manufacturers is to design camshafts that meet the specific needs of various engine types. This includes:

- Conducting extensive research to determine optimal designs.

- Utilizing advanced software for computer-aided design (CAD).

- Collaborating with automotive engineers to ensure compatibility with existing engine technologies.

2. Manufacturing Processes

The manufacturing process of camshafts is intricate and requires high precision. It typically involves:

- Forging: Using high-pressure techniques to shape the camshaft from solid metal.

- Machining: Employing CNC machines to achieve precise dimensions and tolerances.

- Finishing: Applying processes such as grinding and polishing to ensure smooth operation.

3. Quality Assurance

Quality assurance is integral to the production of camshafts. Manufacturers implement stringent testing and quality control measures, including:

- Identifying any material defects through non-destructive testing.

- Ensuring dimensional accuracy with laser measurement tools.

- Conducting performance tests to assess operational efficiency.

Choosing the Right Auto Camshaft Manufacturer

Choosing the right auto camshaft manufacturer can significantly influence the functionality of your diesel engine. Here are some key considerations:

1. Reputation and Experience

Look for manufacturers with a solid reputation in the industry. Companies that have been operational for several years and have established themselves as leaders tend to offer reliable quality.

2. Technological Advancements

It’s essential to consider manufacturers that are at the forefront of technology. Those invested in research and development often produce camshafts that incorporate the latest advancements in material science and engineering.

3. Customer Support and Service

Good customer support is indicative of a manufacturer that values its clients. Look for companies that offer:

- Comprehensive after-sales support.

- Guidance on installation and use of camshafts.

- Warranty and return policies.

Impact of Camshaft Quality on Diesel Engine Parts

In the realm of diesel engines, the quality of components significantly affects the overall engine efficiency and performance. The camshaft is no exception. A well-manufactured camshaft leads to several benefits in diesel engine performance:

1. Power Output Enhancement

A quality camshaft can help increase the power output of a diesel engine by optimizing valve timing and operation. This can particularly benefit performance vehicles and commercial trucks requiring high torque for heavy loads.

2. Fuel Efficiency Improvement

Engine efficiency is closely tied to fuel consumption. By ensuring precise valve opening and closing operations, a well-designed camshaft can lead to better air-fuel mixture and improved combustion, translating to significant fuel savings.

3. Longevity and Reduced Maintenance

Higher-quality camshafts result in lower wear and tear on engine components. This not only extends the lifespan of the engine but also minimizes maintenance issues, providing an overall cost benefit in the long run.

A Look into Spare Parts Suppliers

In conjunction with quality camshaft manufacturers, spare parts suppliers play an equally vital role in the automotive industry. They ensure that the necessary parts are available to both consumers and businesses. The synergy between manufacturers and suppliers is crucial to ensuring the seamless availability of high-quality parts.

The Function of Spare Parts Suppliers

Spare parts suppliers act as intermediaries between manufacturers and end-users, providing access to essential replacement components. Their roles encompass:

- Inventory Management: Maintaining an adequate stock of various parts, especially high-demand items like camshafts.

- Distribution Logistics: Ensuring timely delivery of parts to workshops and consumers to reduce downtime, especially in commercial settings.

- Customer Service: Advising customers on the right parts for their vehicles based on specifications and needs.

Conclusion

In conclusion, the world of auto camshaft manufacturers is essential to the automotive industry, particularly concerning diesel engine parts. Understanding the intricacies of camshaft manufacturing and the critical role it plays in overall engine efficiency can lead to more informed decisions for both consumers and businesses. Quality camshafts contribute to better performance, fuel efficiency, and longevity, while robust spare parts suppliers ensure that these quality components are accessible to all. As the automotive landscape evolves, staying informed and choosing the right partners in manufacturing and supply will be key to success.

For more insights and a wide range of quality diesel engine parts, visit client-diesel.com. Embrace the power of knowledge and quality in the field of automotive components!