The Ultimate Guide to Titanium Fasteners: Superior Performance with Titanium Lock Washers and More

In the rapidly evolving landscape of industrial manufacturing, aerospace, automotive, and high-performance engineering, the significance of high-quality fasteners cannot be overstated. Among the plethora of fastening options available today, titanium fasteners have emerged as *the preferred choice* for professionals who demand *strength, durability, corrosion resistance,* and *lightweight properties*. This comprehensive guide delves into the world of titanium fasteners, with a special focus on titanium lock washers, explaining their advantages, types, and how a leading manufacturer like TitaniumBolts.com ensures top-tier quality.

Understanding Titanium Fasteners: Why They Are the Industry Standard

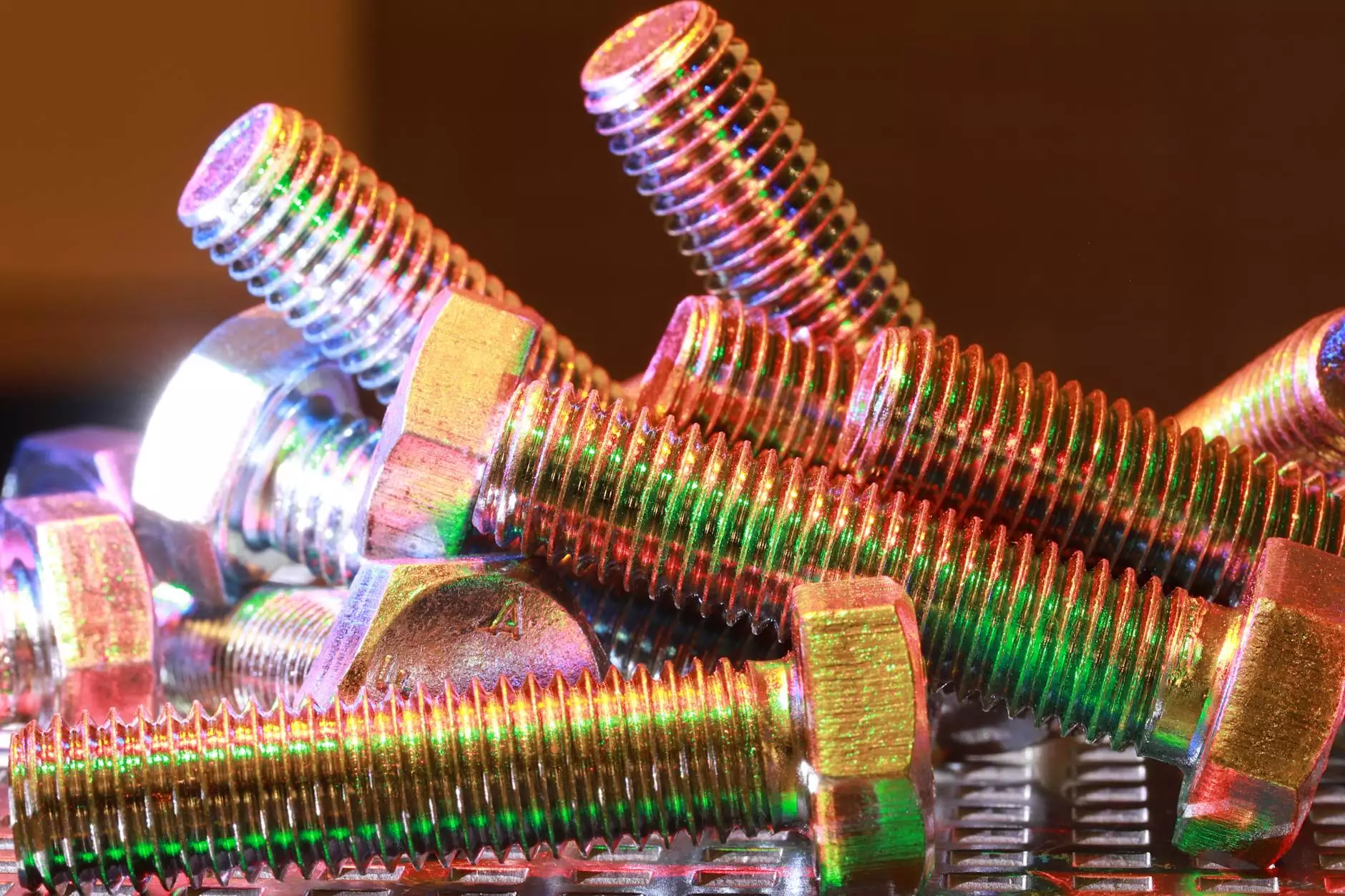

What Are Titanium Fasteners?

Titanium fasteners comprise screws, bolts, nuts, washers, and other fastening components manufactured from *titanium alloys*. Known for their *exceptional strength-to-weight ratio*, these fasteners are indispensable in critical applications where conventional steel fasteners might fall short.

Key Attributes of Titanium Fasteners

- Corrosion Resistance: Titanium naturally forms a protective oxide layer, making it highly resistant to corrosion, particularly in aggressive environments like seawater and chemically laden atmospheres.

- Lightweight: Titanium's density is approximately 60% that of steel, enabling weight reduction without compromising strength.

- High Strength: Despite its lightness, titanium offers *exceptional tensile strength*, ensuring long-term durability under stress.

- Biocompatibility: Titanium is biocompatible, making it ideal for medical applications and implants.

- Temperature Tolerance: Titanium fasteners retain their mechanical properties over a wide temperature range, from cryogenic levels up to 600°C (1112°F).

Applications of Titanium Fasteners in Various Industries

Given their superior properties, titanium fasteners find applications across multiple sectors:

- Aerospace: Essential for aircraft structural components, engine assemblies, and spacecraft due to their lightweight and durability.

- Automotive: Used in high-performance engines, racing cars, and electric vehicles.

- Marine: Ideal for shipbuilding, offshore platforms, and subsea equipment because of their corrosion resistance.

- Medical Devices: Used in surgical tools, implants, and dental components.

- Industrial Equipment: Critical in chemical processing, power plants, and turbine assemblies.

Focus on Titanium Lock Washers: An Essential Component for Secure Fastening

What Are Titanium Lock Washers?

Titanium lock washers are specialized washers designed to prevent threaded fasteners from loosening due to vibrations, torque, or dynamic loads. Made from titanium, these washers combine the *benefits of locking mechanisms* with the *remarkable properties* of titanium materials, ensuring secure and reliable fastening in demanding environments.

Types of Titanium Lock Washers

- Split Lock Washers: The most common type, featuring a split that creates a spring-like tension to prevent loosening.

- Tooth Lock Washers: Have internal or external teeth that bite into the fastener and substrate for enhanced grip.

- Wave Washers: Have a wavy shape providing flexibility and tension to resist loosening.

Advantages of Using Titanium Lock Washers

Integrating titanium lock washers into fastening assemblies offers numerous advantages:

- Superior Corrosion Resistance: Ideal for marine, chemical, and high-moisture environments.

- Weight Reduction: Significantly lighter than steel lock washers, contributing to overall weight savings.

- Enhanced Mechanical Strength: Capable of withstanding high stress and vibration scenarios.

- Long-Term Reliability: Maintains its locking features over prolonged periods, reducing maintenance needs.

- Biocompatibility: Suitable for medical and implant applications where corrosion and biocompatibility are critical.

Choosing the Right Titanium Lock Washer: Factors to Consider

Proper selection of titanium lock washers depends on various factors:

- Application Environment: Corrosive conditions demand high-grade titanium alloys like Grade 5 (Ti-6Al-4V).

- Load and Vibration: Consider the dynamic forces at play to select an appropriate lock washer type.

- Size and Thread Compatibility: Accurate measurements are essential for ensuring fit and effectiveness.

- Material Compatibility: Ensure the washer's material does not react adversely with other components.

- Regulatory and Standards Compliance: Choose washers that conform to industry standards such as ASTM or ISO specifications.

Manufacturing Excellence: How TitaniumBolts.com Leads the Industry

As a premier titanium fasteners manufacturer, TitaniumBolts.com has built its reputation on delivering high-quality products that meet and exceed industry standards. Here’s what sets us apart:

- Advanced Manufacturing Processes: Employing state-of-the-art CNC machining, forging, and heat-treating techniques to ensure precision and durability.

- Rigorous Quality Control: Implementing strict inspection protocols aligned with ISO 9001 standards to guarantee each product’s integrity.

- Custom Solutions: Offering tailored fastener and washer designs to meet specific application needs.

- Material Sourcing: Using only certified titanium alloys, ensuring optimal performance.

- Supply Chain Reliability: Maintaining robust logistics to ensure timely delivery worldwide.

Why Choose Titanium Bolts and Washers from TitaniumBolts.com?

- Unmatched Quality: Our products are manufactured with precision and undergo rigorous testing.

- Extensive Product Range: From standard sizes to custom configurations, we cover all your fastener needs.

- Expert Support: Our technical team provides guidance on material selection, specifications, and best practices.

- Competitive Pricing: We offer premium quality at cost-effective rates, providing excellent value for your investment.

- Global Reach: We serve clients across industries and continents, ensuring your projects succeed regardless of location.

Future Trends in Titanium Fasteners and Lock Washers

The landscape of fastening technology continues to evolve with innovations driven by emerging industries and environmental considerations:

- Enhanced Alloys: Development of new titanium alloys offering even better strength, corrosion resistance, and manufacturability.

- Smart Fasteners: Integration of sensors and IoT technologies for real-time monitoring and predictive maintenance.

- Sustainable Manufacturing: Adoption of eco-friendly processes aiming to reduce environmental impact.

- Expanded Applications: Use in renewable energy sectors like wind and solar, where high-performance fastening solutions are critical.

Conclusion: The Pinnacle of Fastening Excellence with Titanium

Choosing titanium fasteners, specifically titanium lock washers, is a strategic decision that leads to long-term reliability, weight savings, and corrosion resistance in the most challenging environments. Partnering with a reputable manufacturer such as TitaniumBolts.com ensures access to superior quality products backed by expertise, innovation, and commitment to excellence.

Whether you’re in aerospace, marine, medical, or industrial sectors, our comprehensive range of titanium fasteners and lock washers is designed to meet your specific needs. Invest in the future of fastening technology—choose titanium for performance, longevity, and peace of mind.

Contact Us Today

Explore our extensive catalog of titanium fasteners and lock washers or consult our specialists to find solutions tailored to your projects. Experience the difference that top-grade titanium components can make in enhancing your product’s performance and reliability.